Injection moulding is a very interesting phenomenon. The shaping of rubber or plastic articles by injecting heated material into a mould sounds way too interesting isn’t it? Also injection moulding is an extremely flexible method of manufacturing rubber and plastic products. At GIECL, we provide the best injection moulding machines for perform and cap and we provide these machineries to all kinds of industries. Our injection moulding machines can give the desired shape to various mugs, cups, portion multiplates, plates, plastic bowls serving bowls, spoon, lunch boxes and buckets.

After being manufactured in the injection moulding machine the products almost require no work to be done. Once they are ejected from the injection moulds, they are considered as the final outputs. We are renowned for our range of Injection Moulding machineries for production of PET Preform and Cap Closures with all Auxiliaries. All our machines and equipment’s used pumps are manufactured to tight tolerances, high specifications and technical accuracy. Right from Hot air Drier, Auto Loader, Online Color Dosing, Hot Runner Mould and Controller, Chiller, we select the most suitable material for our machineries.

Using our injection moulding machineries it is possible to customize shape and the design. Multifaceted and elaborate shapes can easily be designed and manufactured which otherwise would have been too complex and costly to produce. Once the mould is designed as per client specification, manufacturing various products is a cakewalk for us. It is cost effective because of high production rate.

We ensure that the plastic material used should be very strong and should be able to withstand high temperature during the injection moulding process.

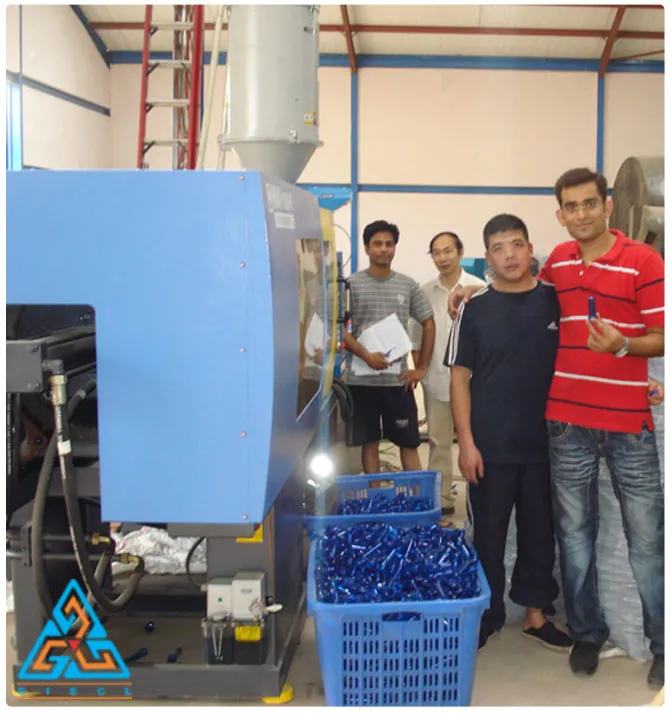

Injection Moulding for Preform and Cap with Online Color Dosing for Blue tinted Preforms

Injection Moulding for Preform and Cap with Online Color Dosing for Blue tinted Preforms

Injection Moulding for Preform and Cap with Chiller

Injection Moulding for Preform and Cap with Chiller

Hot Runner Controller and Mould for Preform and Cap Closers

Hot Runner Controller and Mould for Preform and Cap Closers

Preform Quality has been produced at Sudan

OTHER ITEMS CAN BE PRODCUED

| No | Name | Picture | Size/mm |

| 1 | Mug |  |

110*80*90 |

| 2 | Cup |  |

Φ82*135 |

| 3 | Portion multiplate |  |

Φ215*21 |

| 4 | Plate |  |

Φ170*21 Φ190*25 Φ210*30 Φ227*33 |

| 5 | Basin |  |

Φ260*80 Φ300*90 |

| 6 | Zonse |  |

265*240*115 |

| 7 | SPOON |  |

140 168 |

| 8 | LUNCH BOX |  |

Φ152*55 Φ184*70 Φ185*75 Φ217*90 |

| 9 | BUCKET |  |

10L 16.75L 20L |

© Copyright 1996 - Gujarat Ion Exchange And Chemicals Limited. All Rights Reserved

Powered By: #1 Vinayak InfoSoft - SEO Company Ahmedabad