1. Project Name: Fully automatic shrink packaging machine

fully automatic shrink packaging machine is a high efficiency and continuous operation packing equipment, which designed according to the packaging film thermal shrinkage. It can automatically array, aggregate and align PET beverage bottle or other similar articles, then package it with shrinking film, finally produce finished products after shrinking by heating, cooling and forming. The packaged product is firmly bound with excellent appearance and save the cost. It is specially designed for the printing models.

3.1 The shape is compact and excellent; the frame is novel, unique.

3.2 Lay off film adopts SBJ technical, conveyor film according to color standard sensor electronic sensor quantitative, send film smoothly, and replace film swiftly.

3.3 Using the third generation isothermal sealing cutter, the seal intensity is above cooling sealing cutter 3 times, the seal is even and life is longer.

3.4 Transport systems with speed regulation by frequency variation, the transmission is precise and synchronic.

3.5 Adopting air circulation technology, the shrinkage chamber features rational structure, heat insulation, high precision for temperature control and better packing effects. The import TEFLON coat conveyor belt.

3.6 Disposition: SIEMENS, OMRON, and UNIQUC, etc advanced control component in the world, well equipped.

3.7 The distance between cooling channel and shrinking channel more than 500mm, avoiding the cold wind effect the hot wind to reduce the heat loss.

3.8 The film-sending motor and cycle motor add overload protect device, add OMRON intermediate relay, which save the circuit safety.

The whole machine is composed by the conveyor, packing machine, shrink machine, no-power rear conveyor motor and electrical control, pneumatic control, etc.

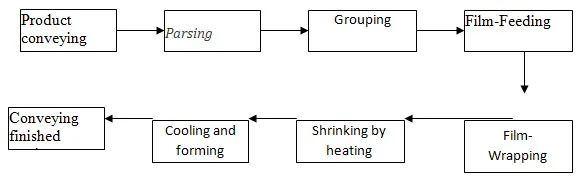

4.1 Packing machine. The packing machine is composed by rack, bottle-dividing body, bottle-pushing body, film-putting body, wrapping body, etc.

4.1.1 The bottle-sending body in charge of sending the PET bottles to the bottle-dividing body, and divide into two parts: fore-conveyor and back-conveyor.

4.1.2 The bottle-dividing body in charge of the PET bottles parsing according to the packing requirement to carry out the promote wrapping film.

4.1.3 The bottle-pushing body in charge of pushing forward the PET bottles and making the film wrapping.

4.1.4 The film-putting body in charge of supplying the PET bottles film wrapping.

4.1.5 Wrapping: According to the packing size, set the packing film size according to detection system, automatic finish wrapped film synchronism during the product moving forward.

4.2 Shrink machine The shrink machine is composed by the three parts: heat shrink, cooling and forming, product conveyor.

4.2.1 Heat shrink machine It is in charge of heating and shrinking the wrappage, to make the film shrink even under the setting temperature, and cling to the wrappage surface, which to carry out the packing purpose.

4.2.2 Cooling and forming It is in charge of cooling the film on the wrappage surface swiftly, which make the film to high strength, and let it easy to handle.

4.2.3 Product conveyor Transport the wrappage to the no-power conveyor; the no-power conveyor belt has the temporary storage function, and it is convenient for staff to palletize or handle.

| 1 | Package efficiency | : | 10~12pcs/min |

| 2 | Applicable container shape | : | quadrate or circular container |

| 3 | Total power | : | 19KW |

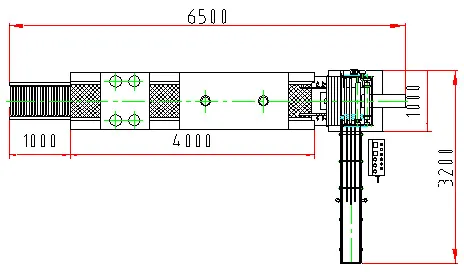

| 4 | Machine size | : | L×W×H=5500×3200×2100 (mm) |

| 5 | Working pressure | : | 0.6~0.8Mpa |

| 6 | Air consumption | : | 0.3 stere/min |

| 7 | Conveyor height | : | 304mm |

| No. | Name | Specifications and Models | Quantity | Remarks |

| 1 | Isothermal sealing cutter | 700 | 1 | Protect technical |

| 2 | PLC controller (core part) | OMRON CPM1A-30CDR-A |

1 | Japan |

| 3 | Motor protector | 3UAI040-0G | 4 | Germany |

| 4 | Color standard sensor | SUNX LX101 | 1 | Japan |

| 5 | Transducer | TAIAN 0.4KW | 3 | Taiwan |

| 6 | Lower- cylinder | UNIQUC GTB40/50-BY | 1 | Taiwan |

| 7 | Pushing cylinder | UNIQUC GTB40/50-BY | 1 | Taiwan |

| 8 | Intermediate relay | OMRON ATE=1=3 | 10 | Japan |

| 9 | Approaches switch | AUT0NICS PRO8-1.5DN | 4 | Korea |

| 10 | Contactor | SIEMENS 3TB4010-0XMO | 4 | Germany |

| 11 | Shrinker mesh belt | DUPONT 600*8350 | 1 | USA |

| 12 | Heating tube | 20*1240*1250W | 12 | China |

| 13 | Sealing and cutting tube | 10*650*1000W | 1 | China |

| No. | Name | Quantity | Material, function,technical character |

| 1 | Transport device | 1 set | 304mm chain, POM material |

| 2 | Aggregating and aligning device | 1 set | Stainless bottle-dividing panel |

| 3 | Film pushing and wrapping device | 1 set | UNIQUC Isothermal sealing cutter |

| 4 | Film lay-out device | 1 set | Detect automatically, motor sending film, stainless film-base stick |

| 5 | Bottle-pressing device | 1 set | Cylinder pressing bottles |

| 6 | Sealing, cutting and seaming device | 1 set | Adopt the third Isothermal sealing cutter 4mm second strength seam |

| 7 | Heating shrink device | 1 set | Adopt the unique air circulation system, FengJuan diversion |

| 8 | Cooling and forming device | 1 set | Cooling tunnel system, enhance cooling, assure the shrink effect |

| 9 | Product conveyor device | 1 set | 1m no-power conveyor system |

| 10 | All the parts contact with the bottles adopt the stainless | ||

Packing process ( make 1.25L,☉89.5mm*H294mm, 3×2 combination as example)

The products transport to the conveyor belt along the filling machine, pass the bottle plate, become two lines, the two lines products transport to baffle, the limit switch sense the two line bottles enter; the conveyor chain stop, cylinder pushes to the cutter, automatic laminator sealing and cutting; then the products enter into the heat shrink machine, heating and forming. After it, it will be sent to the products seat, the stuff take away the packed products.

Automatic Web Sealer with Wrapping Machine – Group Packing Machine

Fully Automatic Group packing machine to pack the bottle in plastic film without tray

GCBS25 Straight Line shrink packing machine

13. Conveyer belt max width: 550mm,

Height of produce line(Adjustable range 150mm)

© Copyright 1996 - Gujarat Ion Exchange And Chemicals Limited. All Rights Reserved

Powered By: #1 Vinayak InfoSoft - SEO Company Ahmedabad